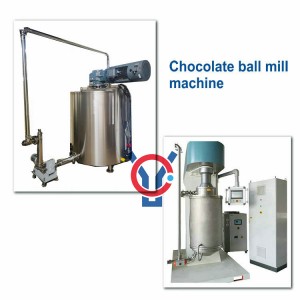

Chocolate Ball Mill Refiner Machine | Production Line

The Chocolate Ball Mill Refiner Machine is utilized to grind and mill chocolate pastes using steel balls within the machine cylinder. As the steel balls collide and create friction with the chocolate pastes, the fineness of the chocolate continuously improves until it reaches the desired level. This machine offers benefits such as high production output, low energy costs, and consistent fineness.

| Model | BT12 | BT50 | BM150 | BM300 | BM500 | BM1000 |

| Capacity | 12L | 50L | 150L | 300L | 500L | 1000L |

| Milling time | 1-2H | 1-2H | 3-4H | 3-4H | 4-6H | 5-8H |

| Motor power | 0.75KW | 7.5KW | 11KW | 15KW | 30KW | 32KW |

| Electric heating power | 3KW | 6KW | 6KW | 6KW | 9KW | 12KW |

| Diameter of grinding ball | 12mm | 12mm | 12mm | 12mm | 12mm | 12mm |

| Weight of grinding ball160 | 20KG | 160KG | 200KG | 300KG | 400KG | 500KG |

| Output fineness | 18-25μm | 18-25μm | 18-25μm | 18-25μm | 18-25μm | 18-25μm |

| Dimension(mm) | 700*610*750mm | 750*800*1820mm | 1000*1100*1900mm | 1400*1200*2000mm | 1400*1500*2350mm | 1680*1680*2250mm |

| G.weight | 80KG | 310KG | 1200KG | 1600KG | 1900KG | 2500KG |

If you want to get not too big capacity, such as 2kg-1000kg per batch or every two hours, this batch type chocolate ball mill is your best choice. You don’t need use chocolate conche, you just need put all raw material into this chocolate ball mill, and then it will mix all material and then make grinding in the same time. Our batch type ball mill advantage is that our machine design can make sure that machine work with stable condition without any problem and it can get better taste chocolate.

This machine is continuous type chocolate ball mill, it should be used along with chocolate refiner and conche, chocolate storage tank and chocolate delivery pump to achieve continuous production and improve production efficiency. It has automatic temperature control.