Factory source biscuit molding machine - Automatic protein bar candy bar making machine – YUCHO GROUP

Factory source biscuit molding machine - Automatic protein bar candy bar making machine – YUCHO GROUP Detail:

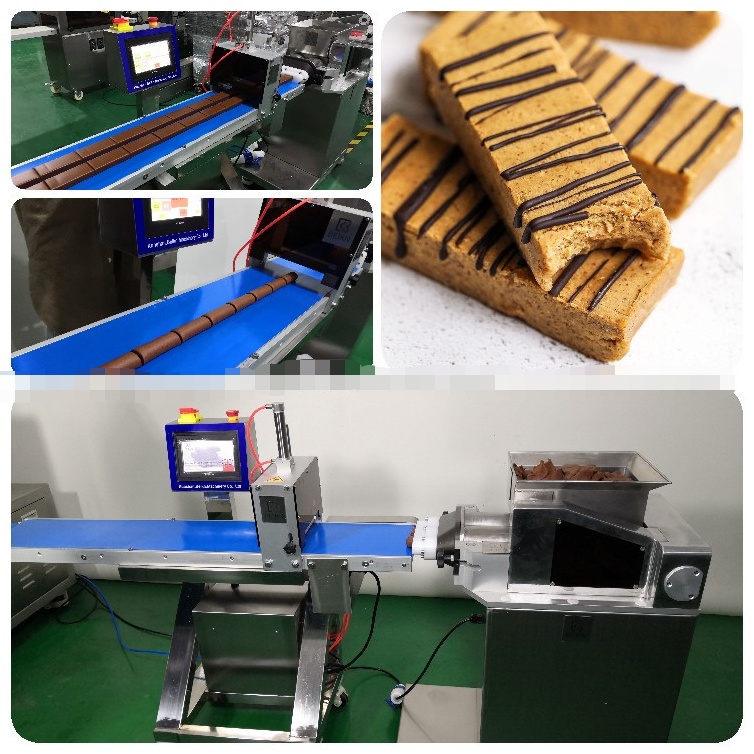

YUCHO offer the complete set full automatic multifuctional candy bar, nougat, cereal bar, fruit jelly bar,

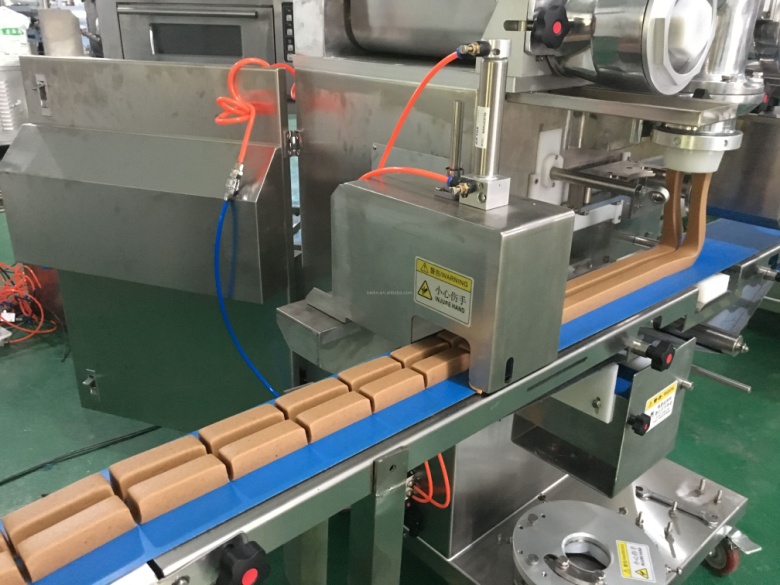

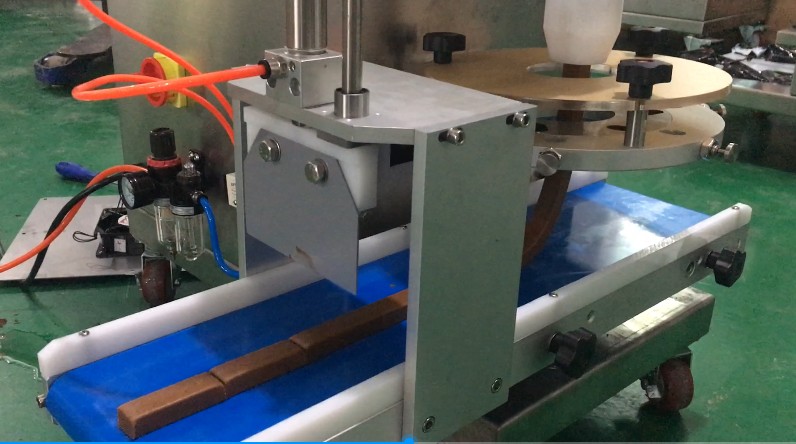

nutritional bar production line base on more than 30 years experience and advanced technology. The production line is mainly used for producing different kind of bars with or without chocolate coating. this line is consists of four main sections: cooking and mixing unit; bar forming unit (including sheet forming, caramel depositing, nuts mixing, cooling, sitting and guillotine); automatic chocolate enrobing and cooling unit; automatic conveying and flow packing unit.

|

Model |

YCS400 |

YCS600 |

YCS800 |

YCS1000 |

YCS5000 |

|

Capacity |

400kg/h |

600kg/h |

800kg/h |

1000kg/h |

1200kg/h |

|

Steam Requirement |

300kg/h, 0.2-0.8MPa |

600kg/h, 0.2-0.8MPa |

900kg/h, 0.2-0.8MPa |

1200kg/h, 0.2-0.8MPa |

1500kg/h, 0.2-0.8MPa |

|

Compressed Air Requirement |

0.9m3/min; 0.6MPa |

1.2m3/min; 0.6MPa |

1.5m3/min; 0.6MPa |

1.8m3/min; 0.6MPa |

2.1m3/min;0.6MPa |

|

Working Condition |

18-25℃ temperature humidity 55% |

||||

|

Workshop Size |

28*4.5*>2.8m |

35*5*>3m |

38*6*>3.2m |

45*8>3.5m |

48*5>3.8 |

|

Electric Power Needed |

65kW/380-220V |

90kW/380V-220V |

110kW/380-220V |

135kW/380-220V |

140kW/380-220V |

|

Weight Of Machine |

17500kg |

20500kg |

23500kg |

26500kg |

28500kg |

|

Industrial Automatic Extruder Protein Bar Production Line Energy Bar Making Machine |

|

|

Model No. |

180C |

|

Capacity |

10-60pcs/min |

|

Production weight |

8-150g/pc |

|

Power |

0.5KW |

|

Voltage |

220V |

|

Machine weight |

100KG |

|

Dimension |

50*130*110cm |

|

Guarantee |

1 Year warranty |

|

Shipping |

15-20 working days |

|

Controller |

Inverter |

|

Condition |

New |

1) 304 stainless steel for machine body, parts in contact with the machine are food grade material.

2) The machine can save 99 kinds of production modes.

3) Simple structure, compact size, user-friendly interface, easy operation,stable and reliable production.

4) The product shape can be adjustable by changing different mould nozzles.

5) Can OEM your size and nozzles according to your requirement.

6) Suitable for different material production and can mix nuts, like butter cookies mateerial, date material,etc.

Besides there are other machine can make different date bars,like these

YCB-280 automatic encrusting machine match with cutter can also make date bar energy bar nuts bar,etc.

YCB-180 Small encrusting machine match with cutter can make date bar energy bar nuts bar,etc.

Product detail pictures:

Related Product Guide:

Our workforce through professional training. Skilled professional knowledge, solid sense of service, to fulfill the services demands of consumers for Factory source biscuit molding machine - Automatic protein bar candy bar making machine – YUCHO GROUP , The product will supply to all over the world, such as: Argentina, Johor, Finland, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!