Industrial Chocolate Dipping Machine Production Line

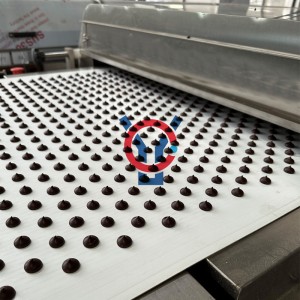

The chocolate dipping machine, also known as the chocolate drops making machine, is designed to produce small drop-shaped or button-shaped chocolate chips. It dispenses chocolate paste through a depositing head onto a PU conveyor belt, delivering the products into a cooling tunnel for automatic cooling and shedding. The chocolate chip making machine offers advantages such as precise amount setting, easy operation, and high production capacity.

The machine's molds are made of stainless steel or polycarbonate plastic, which provides excellent strength, roughness, and demolding performance. Porcelain plates are also commonly used due to their outstanding roughness and demolding characteristics.

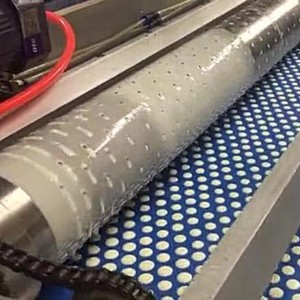

There are two methods for producing chocolate chips: using a pneumatic or servo motor depositor, or utilizing a rolling forming chips machine.

|

Model

Technical Parameters |

400 |

600 |

800 |

1000 |

1200 |

|

Conveyor Belt Width (mm) |

400 |

600 |

800 |

1000 |

1200 |

|

Depositing Speed (times/min) |

0-20 |

0-20 |

0-20 |

0-20 |

0-20 |

|

Single Drop Weight (g) |

0.1-3 |

0.1-3 |

0.1-3 |

0.1-3 |

0.1-3 |

|

Cooling Tunnel Temperature(°C) |

0-10 |

0-10 |

0-10 |

0-10 |

0-10 |

|

Machine Length (m) |

10-30 |

10-30 |

10-30 |

10-30 |

10-30 |

Chocolate Chip Depositor allows for the deposit of chocolate and chocolate compound drops and chips in a variety of shapes and weights, ranging from 0.1 to 5 grams. These types of products are ideal for industrial supply and subsequent melting, for decorating and for use in other products, especially cookies and ice creams.

The Chip Depositor Line includes a double-jacketed depositor head equipped with temperature control and a fixed-speed agitator. The movements of the head are coordinated with the belt used to collect the deposited products. The line also includes a belt-lifting system for deposit enabling diverse drop shapes. The drops are forwarded into cooling tunnel immediately after deposit.

Servo-controlled or Pneumatic-Driven depositor pistons enhanced measuring precision. Optimum tank size and double-jacketed water circulation system for efficient control of deposit temperatures. Easy to remove and clean chocolate agitator and tank. Stainless steel used for operating parts and all components that come into contact with the product. User-friendly screen with specially designed PLC control all of the operating parameters.

This highly versatile machine can be easily adapted to meet new products’ needs, both in terms of design and of changes in shape or weight, simply by replacing the distributor board, a process that takes minutes to complete. It is available in a variety of belt widths, ranging from 400 to 1200mm.