Low price for chocolate machinery manufacturer - chocolate chips depositing machine – YUCHO GROUP

Low price for chocolate machinery manufacturer - chocolate chips depositing machine – YUCHO GROUP Detail:

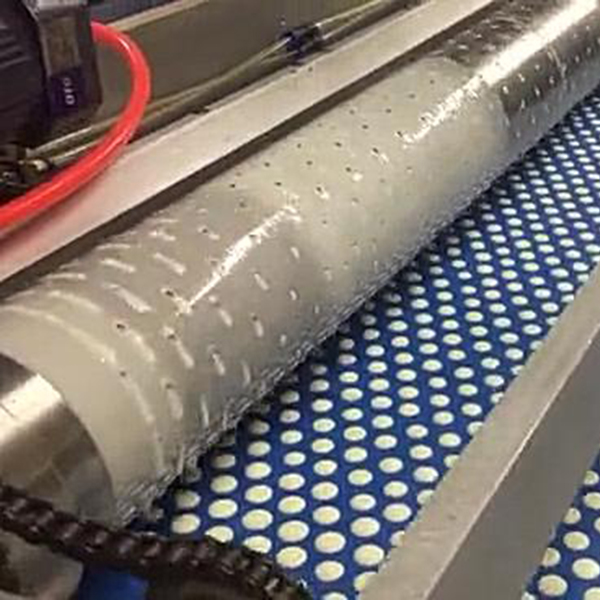

We have two way to produce chocolate chips, one way is depositing type through depositor, another way is rolling type.

QDJ Chocolate Chip Depositing Machine is the dedicated equipment for the production of chocolate chips in small drop-shape or button shape. It can be used to deposit chocolate pastes through depositing head on the PU conveyor belt and delivery the products into the cooling tunnel for cooling down and automatic shedding.

The minimum weight can up to 0.1g per piece. And our machine can produce two color chocolate chips.

The moisture content of the material has a great influence on the viscosity, the water content of raw material and the increase of water absorption in the process of material should be strictly controlled before casting and forming. The water content of the chocolate material used in the pouring is the lowest, no more than 1%.

|

Model

Technical Parameters |

QDJ400 |

QDJ600 |

QDJ800 |

QDJ1000 |

QDJ1200 |

|

Conveyor Belt Width (mm) |

400 |

600 |

800 |

1000 |

1200 |

|

Depositing Speed (times/min) |

0-20 |

0-20 |

0-20 |

0-20 |

0-20 |

|

Single Drop Weight (g) |

0.1-3 |

0.1-3 |

0.1-3 |

0.1-3 |

0.1-3 |

|

Cooling Tunnel Temperature(°C) |

0-10 |

0-10 |

0-10 |

0-10 |

0-10 |

|

Machine Length (m) |

10-30 |

10-30 |

10-30 |

10-30 |

10-30 |

Chocolate Chip Depositor allows for the deposit of chocolate and chocolate compound drops and chips in a variety of shapes and weights, ranging from 0.1 to 5 grams. These types of products are ideal for industrial supply and subsequent melting, for decorating and for use in other products, especially cookies and ice creams.

The Chip Depositor Line includes a double-jacketed depositor head equipped with temperature control and a fixed-speed agitator. The movements of the head are coordinated with the belt used to collect the deposited products. The line also includes a belt-lifting system for deposit enabling diverse drop shapes. The drops are forwarded into cooling tunnel immediately after deposit.

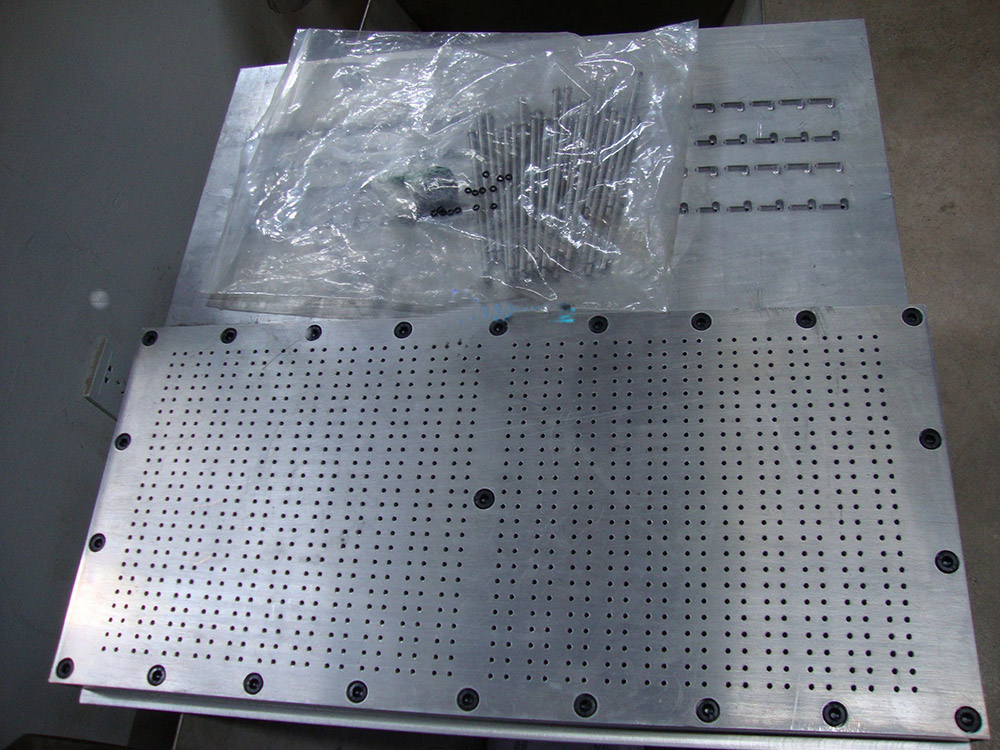

Servo-controlled or Pneumatic-Driven depositor pistons enhanced measuring precision. Optimum tank size and double-jacketed water circulation system for efficient control of deposit temperatures. Easy to remove and clean chocolate agitator and tank. Stainless steel used for operating parts and all components that come into contact with the product. User-friendly screen with specially designed PLC control all of the operating parameters.

This highly versatile machine can be easily adapted to meet new products’ needs, both in terms of design and of changes in shape or weight, simply by replacing the distributor board, a process that takes minutes to complete. It is available in a variety of belt widths, ranging from 400 to 1200mm.

Compact fold wrapping machine for a performance range of up to 260-450 pcs/min. This folding packing machine is mainly packed with solid chocolate, candy, biscuits, Pu’er tea, chicken stock, soap and other hard products. Product packaging of different shapes and sizes can be realized after the mold is changed, such as aluminum wrapping packing.

Chocolate Fold packaging machine could wrap a big sizes range, length of 15-95mm ,width of 15-90mm,height of 4-20mm, But one single chocolate is fixed, the machine is designed and made for that chocolates, if you want to pack a different chocolates, you need to change the molds or buy a new packing machine.

| Product model | YCZ-400 |

| Voltage | 380V/50HZ/3P |

| Power | 7.5KW |

| Dimension(L*W*H) | 6650*1310*1450mm |

| Products size | Length: 16-110 mm Width: 12-90 mm Height: 4-25 mmSpecial sizes upon request. |

| Output | 260-400pcs/min(Based on the size of products) |

| Weight | 2300kg |

| Function | chocolate packing |

| Usage | Hard candy, pressed candy, pralines,chocolate.etc |

| Keyword | Chocolate packing machine |

| Package | wooden case |

It is applied for the pillow packing of products with easy broken surface,such as chocolate,wafer,puffing food,rice cake,cake,Swiss roll,caramel treats,nougat,candy floss and other types of candies or enrobing products.

Main Features

Automatic feeding high speed packing machine

1. NINE Servo motors, touch screen control.

2. Automatic feeding for the complete packing line.

3. Automatic belt speed adjustment through frequency converter, every conveyor belt is individual.

4. Conveyor belt automatic deviation device through cylinder and photocell.

5. Automatic temperature cooling through the air condition with two fans, air cooling or water cooling available.

6 .Double paper rollers, automatic paper splicer device

Product detail pictures:

Related Product Guide:

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for Low price for chocolate machinery manufacturer - chocolate chips depositing machine – YUCHO GROUP , The product will supply to all over the world, such as: Washington, United Arab Emirates, Japan, We take measure at any price to attain essentially the most up-to-date gear and procedures. The packing of nominated brand is our a further distinguishing feature. The solutions to assure years of trouble-free service has attracted a great deal customers. The goods are obtainable in improved designs and richer variety, they're produced scientifically of purely raw supplies. It accessible in a variety of designs and specifications for the selection. The newest forms are much far better than the previous one and they're extremely popular with several clients.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!