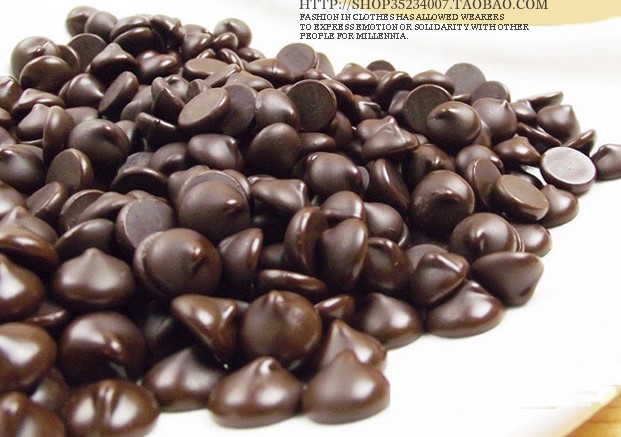

Chocolate chips in today's fast-paced world, advancements in technology have had a significant impact on various industries. The chocolate industry is one such industry that has witnessed tremendous growth and transformation. Among the many innovations in this field, the chocolate chip machine stands out as a leading example. This article explores the evolution, functionality and impact of chocolate chip machines on the chocolate industry.

History and evolution

The origins of chocolate date back thousands of years, originating from the Mayan and Aztec civilizations. However, it was not until the late 18th century that chocolate became more accessible to the masses. The chocolate industry has experienced exponential growth as industrialization and manufacturing advances have allowed the mass production of this delicious treat.

The invention of the chocolate chip machine came about due to the growing demand for conveniently shaped chocolate bars that could be used in a variety of recipes. Until now, chocolate was mainly consumed in solid or liquid form. The need for a machine capable of producing uniformly sized chocolate chips soon became apparent, prompting inventors to seek to create an automated solution.

Initially, the chocolate chip production process was done by hand. Chocolatiers manually cut chocolate bars or bars into small pieces that are then used in baking and confectionary recipes. Although effective, this method is time-consuming and often results in unevenly sized chocolate chips. The invention of the chocolate chip machine revolutionized this process by automating and streamlining the process.

Features and components

Modern chocolate bar making machines consist of several key components that work together to produce perfectly shaped chocolate chips. The machine usually consists of a large hopper, a conveyor belt, slicing blades and a collection chamber. The process begins by loading chocolate wrapping machines chunks or bars into a hopper, where they are heated to a specific temperature to ensure a smooth consistency.

Once the chocolate is melted, it's sent to a conveyor belt that carries it to the slicing blades. The slicing blade is adjustable to customize the chocolate chip size to specific requirements. As the chocolate passes through the blade, it is systematically cut into uniformly sized chocolate chips. The pieces then fall into collection chambers, ready to be packaged and distributed to manufacturers, bakeries and confectionary companies around the world.

Impact on the chocolate industry

The introduction of chocolate chip machines had a profound impact on the chocolate industry. Here are some of the key areas where this technology is revolutionizing the industry:

1. Improve efficiency: Before the invention of the chocolate chip machine, the process of manually chopping chocolate was labor-intensive and time-consuming. The automated production line provided by the machine significantly improves efficiency and can produce more chocolate chips in less time.

2. Consistency and Uniformity: The chocolate chip machine produces uniformly sized chocolate chips, ensuring consistency in baking and confectionery applications. This level of precision improves the quality and appearance of chocolate-related products, allowing manufacturers to maintain standardized products.

3. Cost-Effectiveness: The automated production process facilitated by the chocolate chip machine reduces labor costs and minimizes material waste. By streamlining the production process, manufacturers are able to lower the price of chocolate chips, making them more accessible to a wider group of consumers.

4.Versatility and Innovation: The availability of chocolate chips in the market has opened up a world of opportunities for culinary creativity and innovation. Bakers and chefs can now experiment with a variety of recipes incorporating chocolate chips, leading to a proliferation of unique and creative chocolate creations.

The following are the technical parameters of chocolate chip making machine:

Technical Data:

|

SPECIFICATIONS FOR Chocolate Drop Chip Button Machine With Cooling Tunnel |

|||||

| Model | YC-QD400 | YC-QD600 | YC-QD800 | YC-QD1000 | YC-QD1200 |

| Conveyor Belt Width (mm) | 400 | 600 | 8000 | 1000 | 1200 |

| Depositing Speed (times/min) |

0-20 |

||||

| Single Drop Weight |

0.1-3 GRAM |

||||

| Cooling Tunnel Temperature(°C) |

0-10 |

||||

Chocolate chips

Post time: Oct-19-2023