Gummy candies have been a favorite treat for people of all ages for many years. The delightful chewy texture and vibrant flavors make them irresistible, but have you ever wondered how these delectable treats are made? The answer lies in the gummy machine. In this article, we will dive into the world of gummy candy makers, exploring their history, functionality, and the process of making gummy candies.

History of Gummy Candy Makers:

Gummy candies have a rich history that dates back to the early 1900s. The first gummy candies were invented in Germany by Hans Riegel, who founded Haribo, a brand that still dominates the market today. Initially, gummy candies were handmade, limiting their production capacity.

However, as the popularity of gummy candies grew, there arose a need for a more efficient and automated process. This led to the invention of the gummy machine, which revolutionized the production of gummy candies and paved the way for mass production.

Functionality of a Gummy Machine:

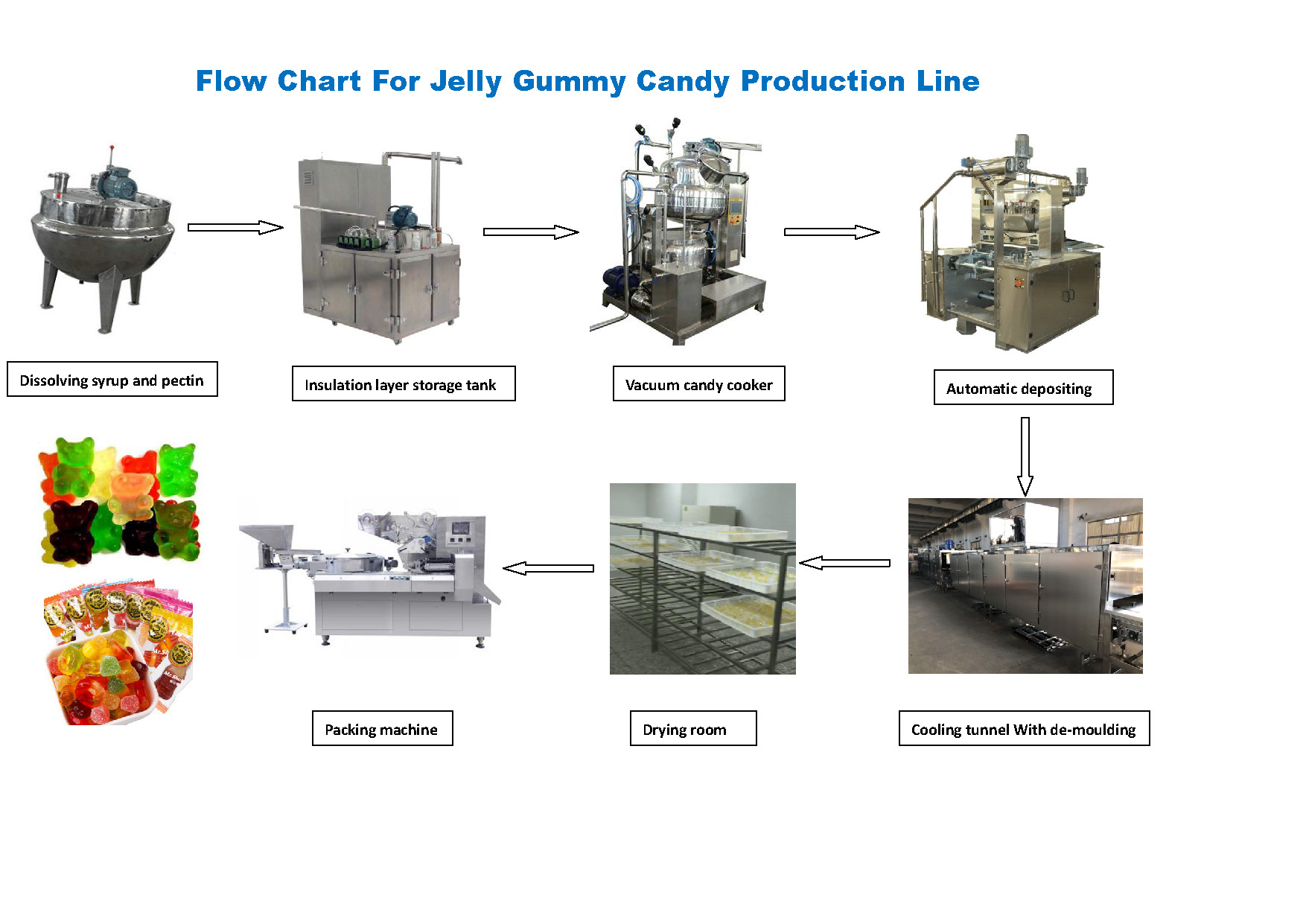

A gummy machine is a specialized piece of confectionery equipment designed to create gummy candies in large quantities. These machines consist of various components working together to produce the final product. Let's explore the key functionalities of a gummy machine:

1. Mixing and Heating: The process begins with the mixing of ingredients such as gelatin, sugar, water, and flavorings in a large mixing bowl. The mixture is then heated to a specific temperature to achieve the desired consistency.

2. Shaping: Once the mixture is ready, it is poured into individual molds that determine the shape and size of the gummy candies. The molds are made of food-grade silicone or starch to ensure easy removal of the candies later.

3. Cooling and Drying: After shaping, the gummy candies undergo a cooling process to solidify them. This is often done in a cooling tunnel, where cold air is circulated to lower the candies' temperature. Once cooled, the candies are removed from the molds and laid out for further drying to remove any excess moisture.

4. Coating and Packaging: Lastly, the gummy candies may go through a coating process to add shine or a sugar coating. These candies are then packaged in colorful wrappers or bags before being distributed to stores and consumers.

Advancements in Gummy Machine Technology:

Over the years, gummy making machine technology has witnessed remarkable advancements, allowing for greater efficiency, flexibility, and customization options. Here are some notable advancements in the field:

1. High-Speed Production: Modern gummy machines can produce thousands of gummy candies per hour, thanks to faster mixing, molding, and cooling processes. This has enabled manufacturers to meet the ever-increasing demand for gummy candies worldwide.

2. Customized Shapes and Flavors: Gummy machines now come with interchangeable molds, allowing manufacturers to create a wide variety of shapes and sizes. Moreover, they can easily incorporate different flavors and colors into their candies, providing consumers with endless options.

3. Automated Controls: To enhance production efficiency, gummy machines are equipped with advanced automation features. These include touch-screen interfaces, programmable settings, and real-time monitoring systems, ensuring consistent quality and minimizing human errors.

Gummy candies have become a staple in the confectionery industry, and gummy machines have played a crucial role in their mass production. From the humble beginnings of handmade candies to the automated processes of modern gummy machines, the evolution of gummy candy production has been truly remarkable.

With their ability to mix, shape, cool, and coat gummy candies, these machines have transformed the industry, making it possible for us to enjoy our favorite gummy treats in abundance. So, the next time you indulge in a tasty gummy candy, take a moment to appreciate the intricate process that went into its creation, courtesy of the gummy making machine.

Post time: Aug-08-2023