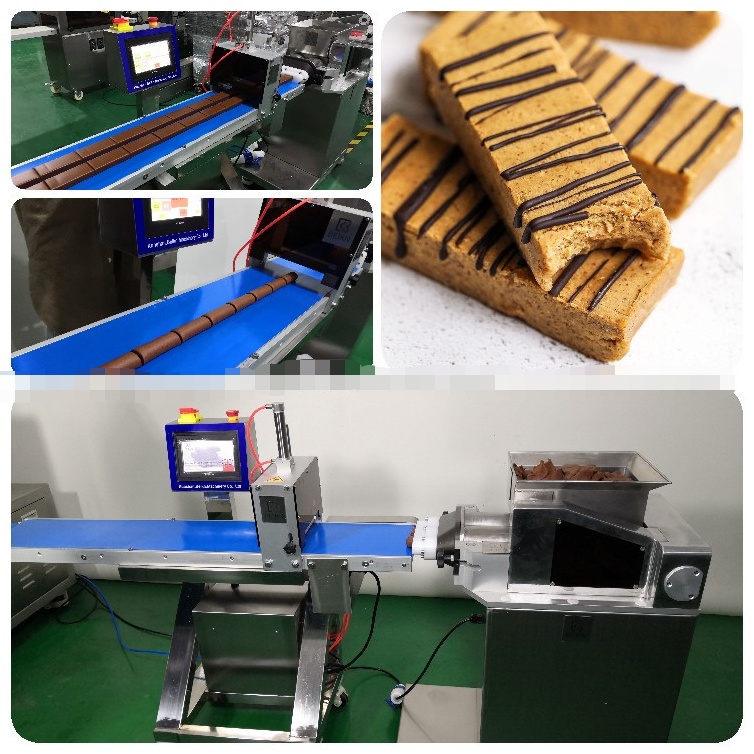

Protein Ball Rolling Machine Production Line

YUCHO offer the complete set Protein Ball Rolling Machine Production Line.

Snickers bar production line base on more than 30 years experience and advanced technology. The production line is mainly used for producing different kind of bars with or without chocolate coating.This line is consists of four main sections: cooking and mixing unit; bar forming unit (including sheet forming, caramel depositing, nuts mixing, cooling, sitting and guillotine); automatic chocolate enrobing and cooling unit; automatic conveying and flow packing unit.

Kitchen system:

a. Auto-weighing and dissolving system

b. Aerating cooker for nougat

c. Double"Z" blade mixer

e. Caramel cooker

Forming system:

a. Nougat layer roller

b. Caramel layer roller

c. Nuts sprinkler (Option)

d. Cooling Tunnel

e. Longitudinal Cutters

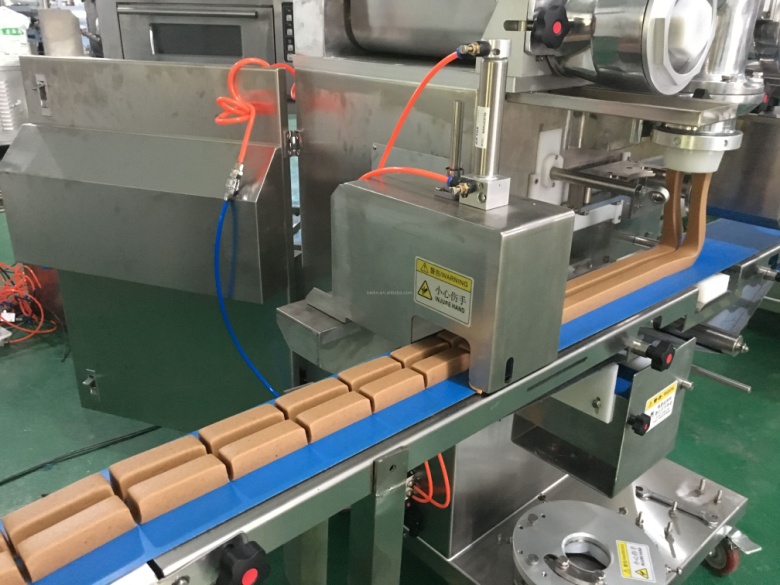

f. Ropes Separator

g. Guillotine

h. Enrober and cooling tunnel

Auto-packing system

Automatic aligner plant and servo driving flow wrapping machine

|

Model |

YCS400 |

YCS600 |

YCS800 |

YCS1000 |

YCS5000 |

|

Capacity |

400kg/h |

600kg/h |

800kg/h |

1000kg/h |

1200kg/h |

|

Steam Requirement |

300kg/h, 0.2-0.8MPa |

600kg/h, 0.2-0.8MPa |

900kg/h, 0.2-0.8MPa |

1200kg/h, 0.2-0.8MPa |

1500kg/h, 0.2-0.8MPa |

|

Compressed Air Requirement |

0.9m3/min; 0.6MPa |

1.2m3/min; 0.6MPa |

1.5m3/min; 0.6MPa |

1.8m3/min; 0.6MPa |

2.1m3/min;0.6MPa |

|

Working Condition |

18-25℃ temperature humidity 55% |

||||

|

Workshop Size |

28*4.5*>2.8m |

35*5*>3m |

38*6*>3.2m |

45*8>3.5m |

48*5>3.8 |

|

Electric Power Needed |

65kW/380-220V |

90kW/380V-220V |

110kW/380-220V |

135kW/380-220V |

140kW/380-220V |

|

Weight Of Machine |

17500kg |

20500kg |

23500kg |

26500kg |

28500kg |

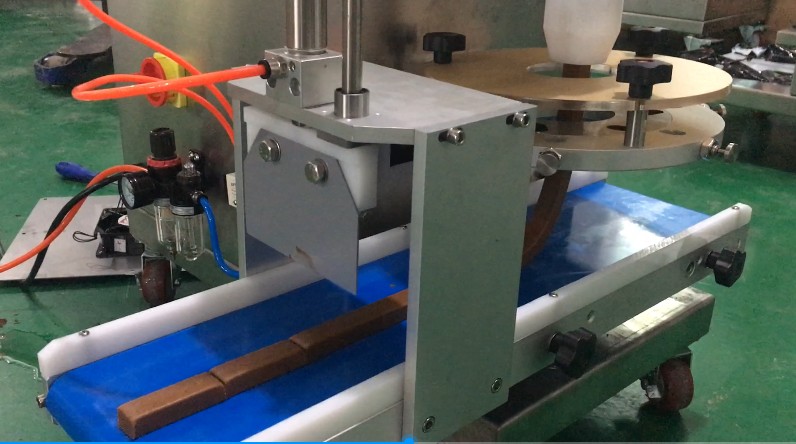

Besides there are other machine can make different date bars,like these

YCB-280 automatic encrusting machine match with cutter can also make date bar energy bar nuts bar,etc.

YCB-180 Small encrusting machine match with cutter can make date bar energy bar nuts bar,etc.